RoboPower Provides Great Production Flexibility at PN Beslagfabrik

Flexible solution opens up to new possibilities

The first robot is installed at Peder Nielsen Bracket Factory in Brønderslev, and after just one month of operation, it runs 24 hours a day, 5 days a week.

High production flexibility

User-friendly software

Payback period under one year

24 hours a day, 5 days a week

Challenge

PN in Brønderslev was looking for a semi-automatic solution for handling items in the factory. It has been a long-standing desire to implement automation, but no solution was previously the right one.

Solution

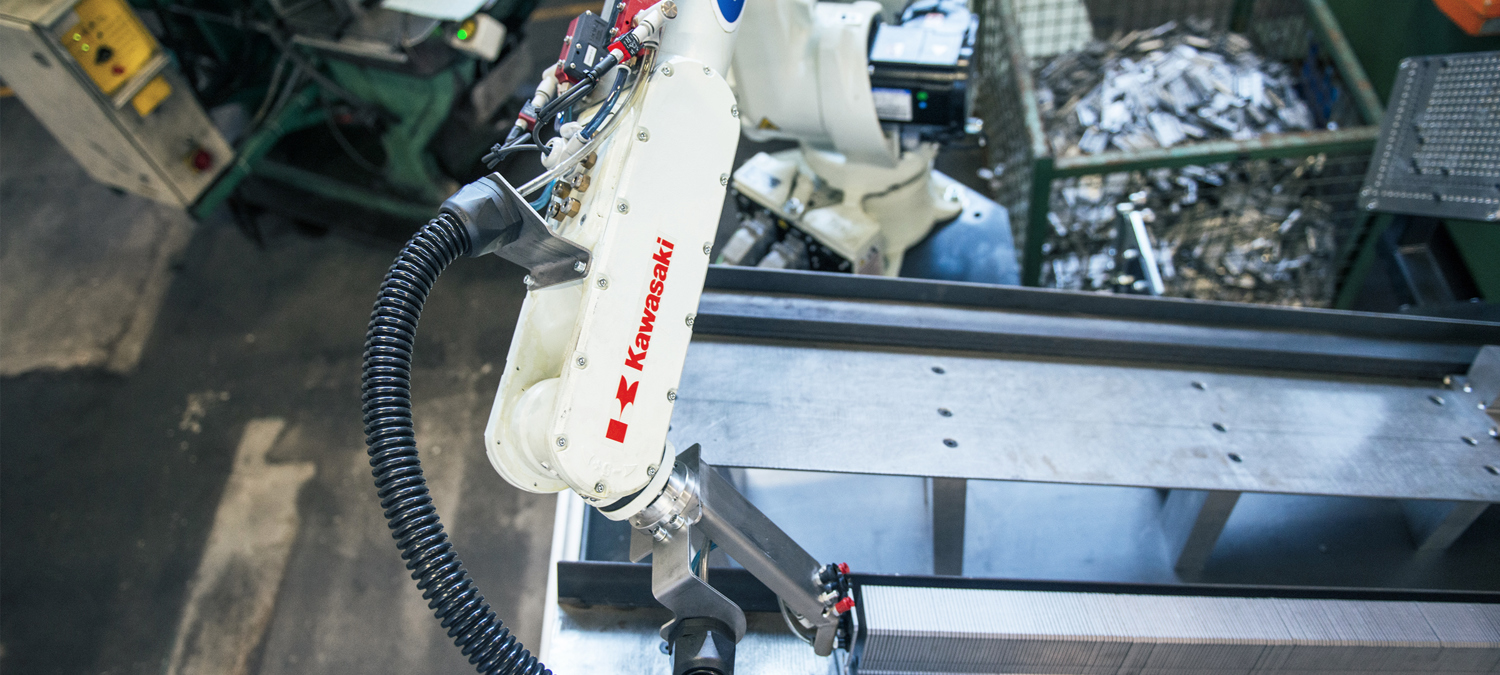

A handling robot from BILA turned out to be the perfect fit for PN. BILA could meet PN's budgetary requirements and provide them with a flexible solution with many future possibilities.

Profit

With a semi-automatic solution from BILA, PN has streamlined their production and laid the first building block for further automation in the future.

PN has delivered quality craftsmanship to leading hardware stores and tool depots for over 140 years, primarily in the Nordic region. They had previously explored many different fully automated solutions for handling items in the factory, but each time it had become too expensive.

With the choice of a BILA RoboPower, the factory has obtained a standard semi-automatic solution that meets their requirements for flexibility and investment level.

"We have chosen a flexible solution with the possibility of further developing the system. This means that we have started at a reasonable cost, and with our own skilled toolmakers, we have expanded the system ourselves,"

- Jesper Bangsborg, CEO

The factory's own expansion of the system by adding a loading system has meant that they now have a fully automated system that keeps three punching machines running and operates around the clock with only two daily magazine refills.

It is not only the investment amount that is reasonable. The payback period of less than a year is an important parameter, as is the flexibility in the robot cell, which has been a crucial factor in choosing the RoboPower robot. PN's own employees have received training in programming and adapting the robot cell, which means they are very self-sufficient and can, for example, move items onto the robot system themselves.

"When we have a good idea, we just run it by BILA's technicians to ensure that our ideas also work in practice. That way, we can quickly create new fixtures for new items, and thus we can start up new items faster and cheaper than if we had to call in external technicians,"

- Jesper Bangsborg, CEO

More robots on the way

The collaboration regarding the installation and commissioning of the BILA RoboPower solution has worked well, and with the evident benefits of automation in production, there are already several robots on the way to PN.

"The first robot has provided us with documentation of the impact of automating our processes, and therefore, an optimisation plan has been developed for the entire factory, so we can enhance our competitiveness all around,"

- Jesper Bangsborg, CEO

The next BILA RoboPower is already being installed and will be producing post supports in collaboration with a punching machine and a circular seam welder from Migatronic. Before Christmas, the third BILA RoboPower will be installed, and it will initially work in conjunction with two additional punching machines.

Get 360 degree consultation about your setup, and let us help you elevate your automation aspirations to the next level. You can contact us at +45 9771 0044.

Contact us

We are ready to answer all your

questions and have a non-committal

conversation about the possibilities

with production optimisation in your company.