Palletising Frees Up Employees from Heavy Lifting at Danpo Aars

Efficient Food Palletising

15 boxes per minute

Improved competitiveness

Reduced handling time

Better work environment

Industrial automation - Palletising of food

Danpo Aars aimed to automate palletising in the bulk packaging department to create more space, enhance the physical work environment, and reduce labour costs.

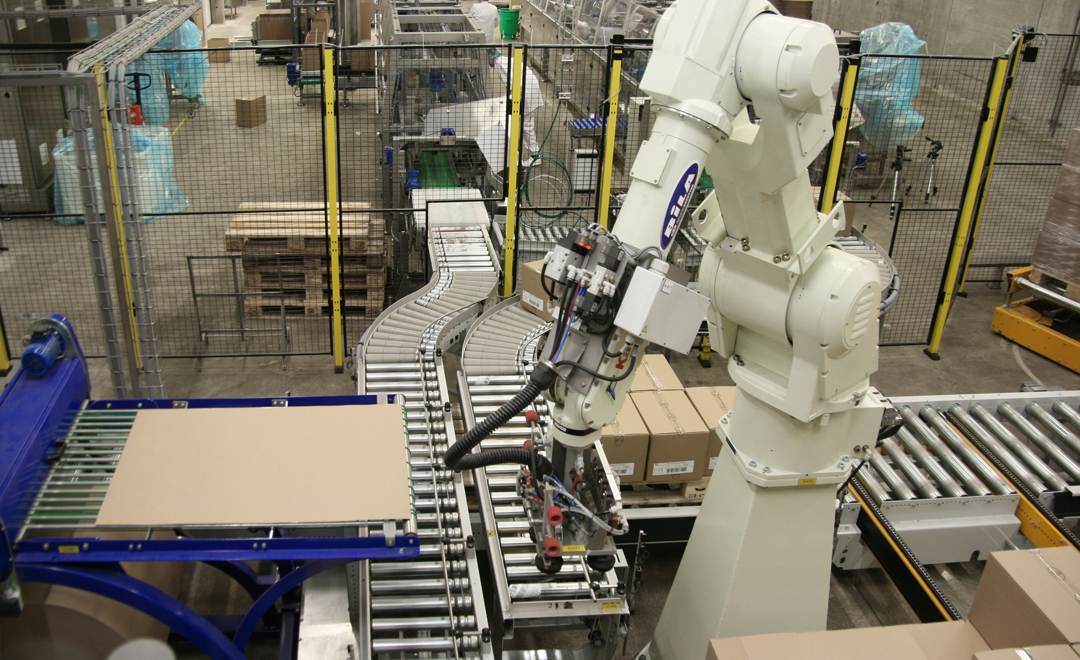

The solution was a robot system from BILA that automatically sorts and palletises boxes from up to 4 production lines. The system can handle up to 15 boxes/minute per robot.

"The system was delivered on time despite a very short schedule, and our manpower needs for palletising have been significantly reduced. It's a good business. Additionally, we have relieved our employees of many heavy lifts, thus improving our work environment,"

Per Alan Jensen, Production Director

Get 360 degree consultation about your setup, and let us help you elevate your automation aspirations to the next level.

You can contact us at +45 97 71 00 44.

Contact us

We are ready to answer all your

questions and have a non-committal

conversation about the possibilities

with production optimisation in your company.