Heede Bolcher Automates Sweets Palletising with Customised Solution

New requirements for production equipment

Heede Bolcher - a privately owned Danish company that manufactures and sells sweets in Denmark and neighbouring markets. Heede Bolcher has been producing candies since 1920 and today produces a wide range in various flavours, colours, and shapes.

Increased efficiency

Improved work environment

Enhanced employee satisfaction

Automation on limited space

Challenge

Heede Bolcher prioritises investing in modern production equipment to ensure the production of a wide range of quality sweets at competitive prices. In the past, sweets were manually stacked by employees who had to lift the heavy sweets boxes.

Solution

The solution to their challenges was a BILA Flex solution, which included a floor-mounted pallet stacker and a fully automated lane for pallets. BILA Flex allows the customer to customise the solution according to their specific needs, whether it involves adding infeed lanes, conveyors, or other equipment.

Profit

Heede Bolcher achieves a production rate of 480 units per hour and experiences a significant improvement in safety in the production area where the robot is in operation.

A customised BILA-solution

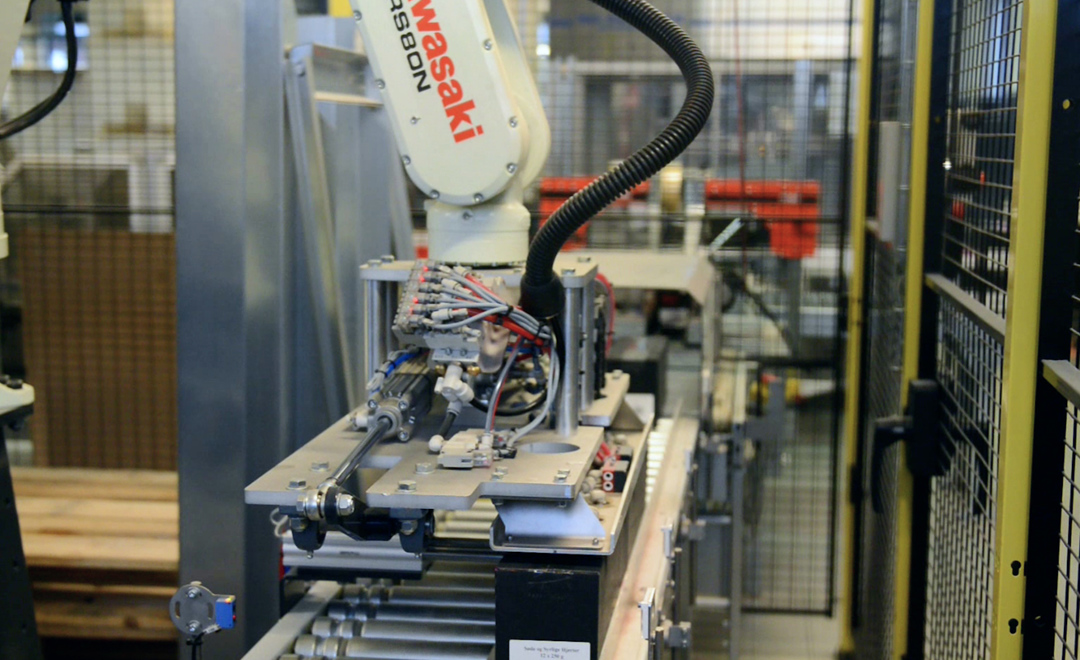

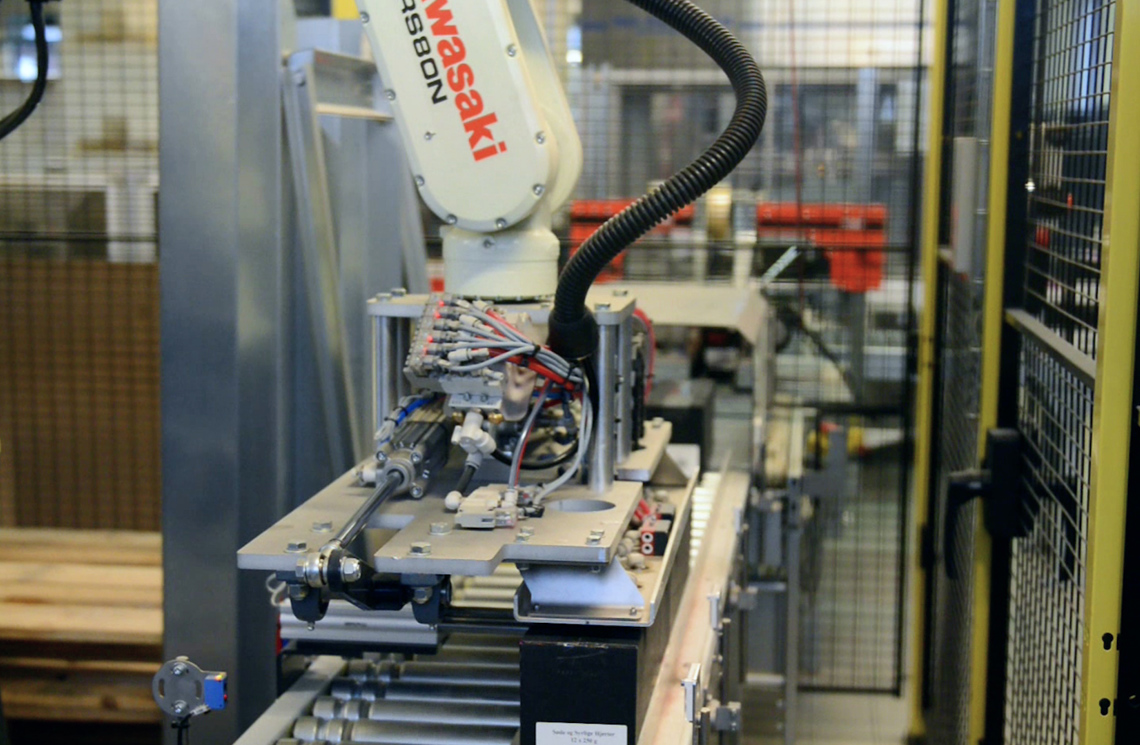

BILA provides a standard Kawasaki robot with a few tailored adjustments that automate a palletising process previously handled manually.

Heede Bolcher prioritises having modern and efficient production equipment as a key focus, enabling them to produce a wide range of high-quality sweets at a competitive price. Previously, the palletising of candies was done manually, with an employee physically lifting the boxes of sweets onto pallets.

”We saw significant potential for streamlining by automating our palletising process, while also aiming to enhance operational reliability and spare our employees from heavy, repetitive tasks. We view an automation solution as an investment in the future,”

Søren Elkjær Vang, Managing Director

They chose a customised standard solution

The solution was a Kawasaki robot with a floor-mounted pallet stacker and a fully automated outfeed lane for full pallets. The solution allows the customer to customise according to their needs, whether it's infeed lanes, conveyors, or other equipment that needs to be connected. The automation solution prioritises user-friendliness and flexibility, while taking only about a day to assemble and install. Regarding the implementation phase, Søren Elkjær Vang describes:

”The entire implementation process was smooth, seamless, and executed with a high level of professionalism. It was characterised by good chemistry and proactivity from both parties,”

Søren Elkjær Vang, Managing Director

Reliable production and happy employees

Heede Bolcher initially encountered some resistance to the robot after implementation, but the employees quickly embraced it, and today, they would be reluctant to do without it. "We have much happier employees now, and the operational reliability is top-notch," emphasises Søren Elkjær Vang. Heede Bolcher runs 480 units per hour and experiences a very high level of safety where the robot operates. "After an overall assessment of price, solution quality, and the chemistry between us, we had no doubt that BILA was the right choice to tackle the task. We would recommend BILA to others at any time," says Søren Elkjær Vang, Managing Director at Heede Bolcher.

Get 360 degree consultation about your setup, and let us help you elevate your automation aspirations to the next level.

You can contact us at +45 97 71 00 44.

Contact us

We are ready to answer all your

questions and have a non-committal

conversation about the possibilities

with production optimisation in your company.