Arla Branderup Automates Mozzarella Production

Arla Branderup transforms production

Arla Branderup has, with their new investment, shifted from producing yellow cheese to mozzarella. In this transformation, the capacity is expanded from 18,000 tons to 25,000 tons of cheese per year, along with the approximately 80 employees at the dairy.

Technical solution for a specific need

Close and flexible collaboration

On-time delivery and implementation

4500-6500 kg of mozzarella per hour

Challenge

Arla in Branderup wanted to expand the capacity for mozzarella. It was crucial to have a future-proof solution with development potential.

Solution

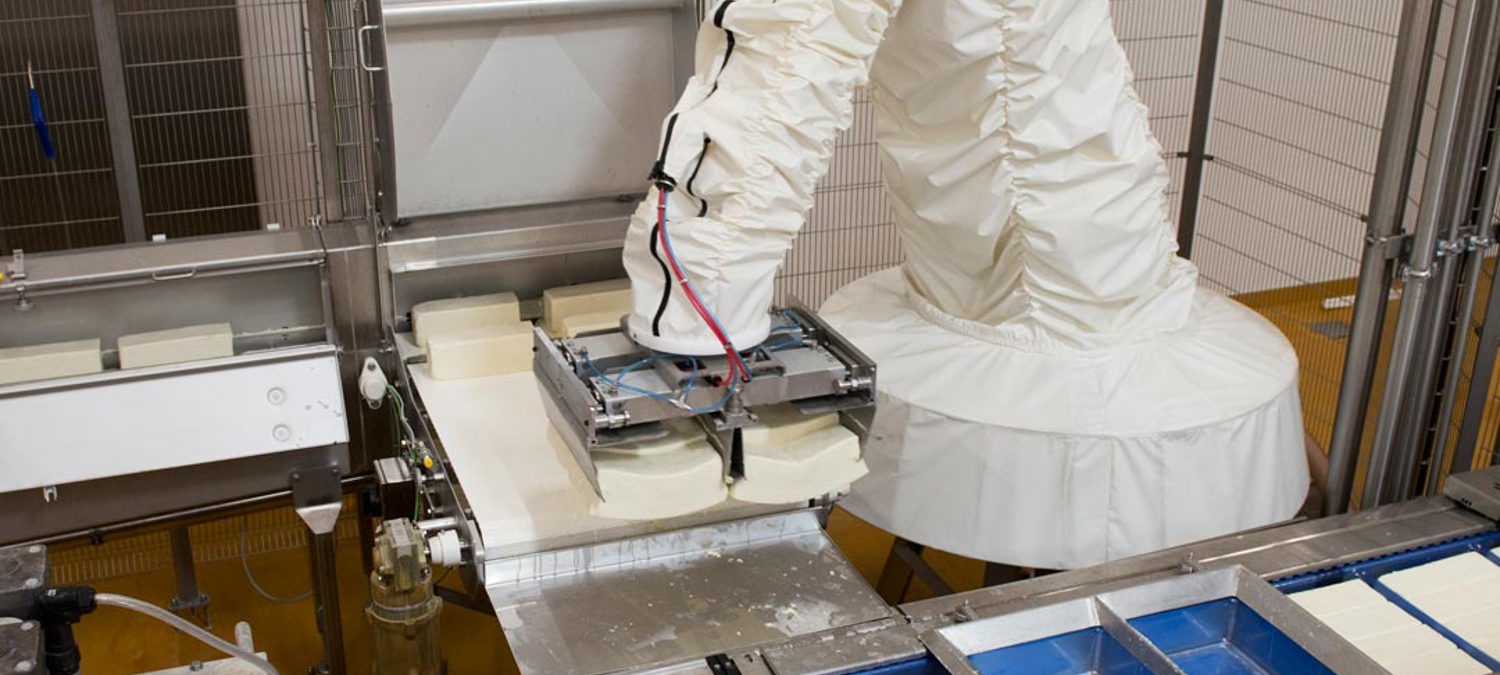

The automation solution includes 4 robots, of which 2 are reused from the dairy's previous production, and 2 are new Kawasaki robots from BILA. The systems handle mozzarella in the packaging and palletising phases.

Profit

The solution currently handles 2.5 million mozzarella packages annually. This means that the production line packages 1 billion individual mozzarella fillets each year.

Collaboration on a new mozzarella line

BILA designs a solution with 4 robot cells and a new solution with pressureless accumulation, developed in close collaboration with Arla Branderup to meet the dairy's restructuring needs. Mozzarella is a growing product globally, and Arla struggled to keep up with demand. Therefore, they wanted to increase mozzarella capacity by reconfiguring the Branderup dairy, where yellow cheese was previously produced. Hence, they needed an entirely new line for a new product. Arla produces mozzarella in its dairy in Roedkaersbro with a BILA solution, allowing many details from this project to be reused.

"We needed to expand the capacity for mozzarella. It was essential for us to have a future-proof solution with development potential, as we have plenty of room to grow in Branderup,"

Michael Schlosser Johansen, Logistics Manager

BILA designs mozzarella solution

Arla chose BILA as the supplier for the Branderup solution. The solution includes 4 robots, of which 2 are reused from the dairy's previous production, and 2 are new Kawasaki robots from BILA. The systems handle mozzarella cheese in the packaging and palletising phases. The first robot handles loading in deep draw with subsequent vacuum packaging in foil and weight checking. Mozzarella fillets are vacuum-packed in sets of 4, after which the packages are moved on a conveyor belt with pressureless accumulation. The pressureless accumulation is a BILA invention that ensures the cheeses do not sustain pressure damage.

The second robot palletises the cheese packages in plastic crates before the pallets are picked up by the dairy's forklift drivers, who transport the cheese for a 5-day refrigeration. After cooling, the third robot reorganises the mozzarella. The cheese is depalletised and placed on a new conveyor belt, where each package undergoes another weight check. The last step is handled by the fourth robot, which palletises the packages directly onto pallets before the pallets are finally wrapped, and the mozzarella is ready for further distribution.

A smooth-running line with expansion possibilities

The robot line is implemented at Branderup and can currently handle 2.5 million mozzarella packages annually. In other words, the line packages 1 billion individual mozzarella fillets each year. Michael discusses the development and implementation phase:

"In the ideation phase, we had many different sketches on the drawing board. We worked closely together, and the solution evolved as we continually gained insights into the dairy's needs. BILA has been particularly skilled in the solution phase with many constructive suggestions," says Michael Schlosser Johansen, Logistics Manager

The line was quickly implemented, and the project was delivered on time to the dairy. The project was designed with the possibility of both expanding with a new line and connecting an AGV if the need arises in the future. The first part of the system currently handles 4500 kg of mozzarella per hour and is designed with the potential to expand the capacity to 6500 kg per hour.

"BILA is a preferred supplier and has been a close collaborative partner in the project. We felt like one team. Today, our cheeses are handled very gently, and we have received a well-functioning system that fully meets our expectations,"

Michael Schlosser Johansen, Logistics Manager

Get 360 degree consultation about your setup, and let us help you elevate your automation aspirations to the next level.

You can contact us at +45 97 71 00 44.

Contact us

We are ready to answer all your

questions and have a non-committal

conversation about the possibilities

with production optimisation in your company.